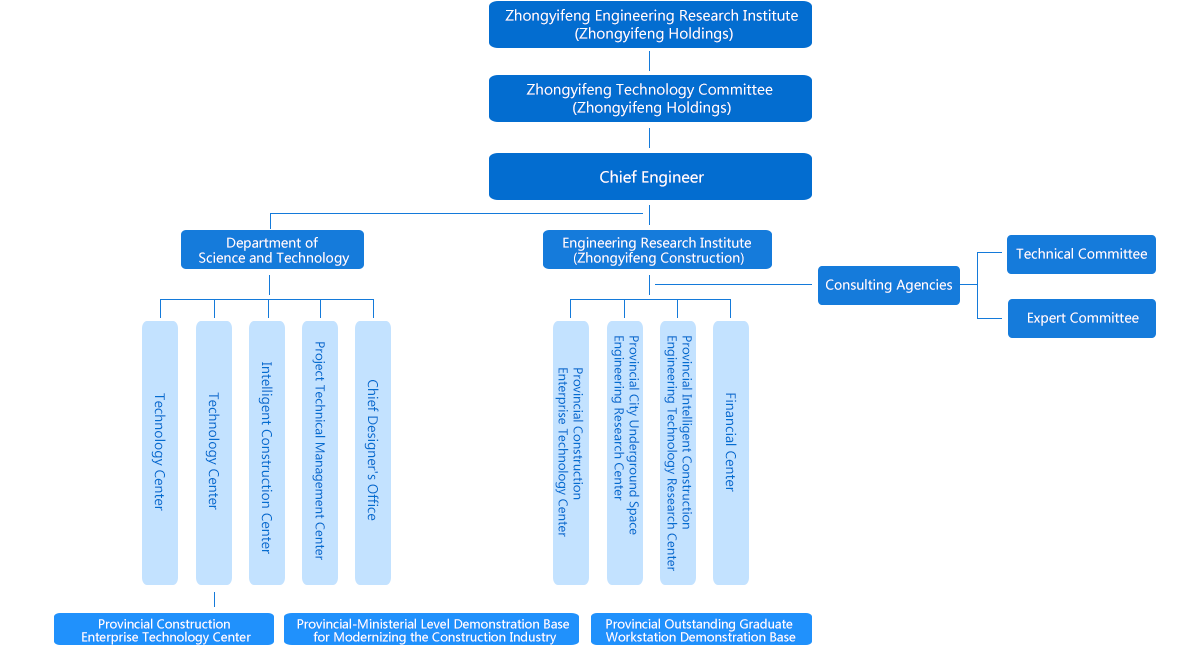

TECHNOLOGY CENTER

SCIENTIFIC RESEARCH SYSTEM

LEAN CONSTRUCTION

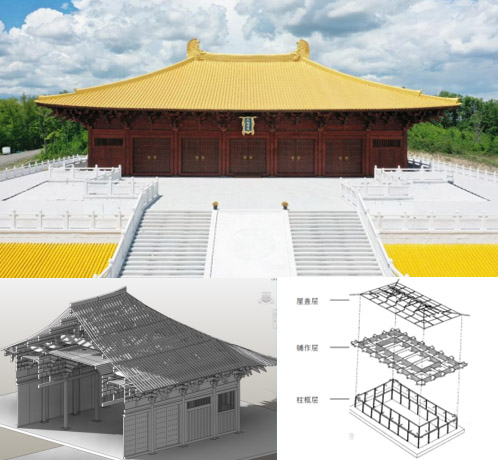

Key Construction Technology for Multi-Faceted Large-Span Bi-directional Cross-Tensile Timber Beam Roof

Innovative Technology Applications at Suzhou Modern Media Plaza

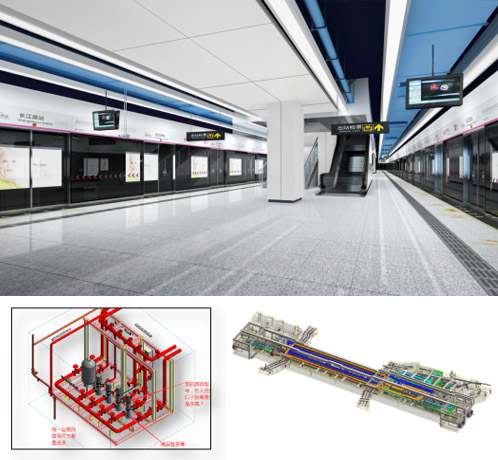

Circular-cutting pushing method for the construction of connecting tunnels

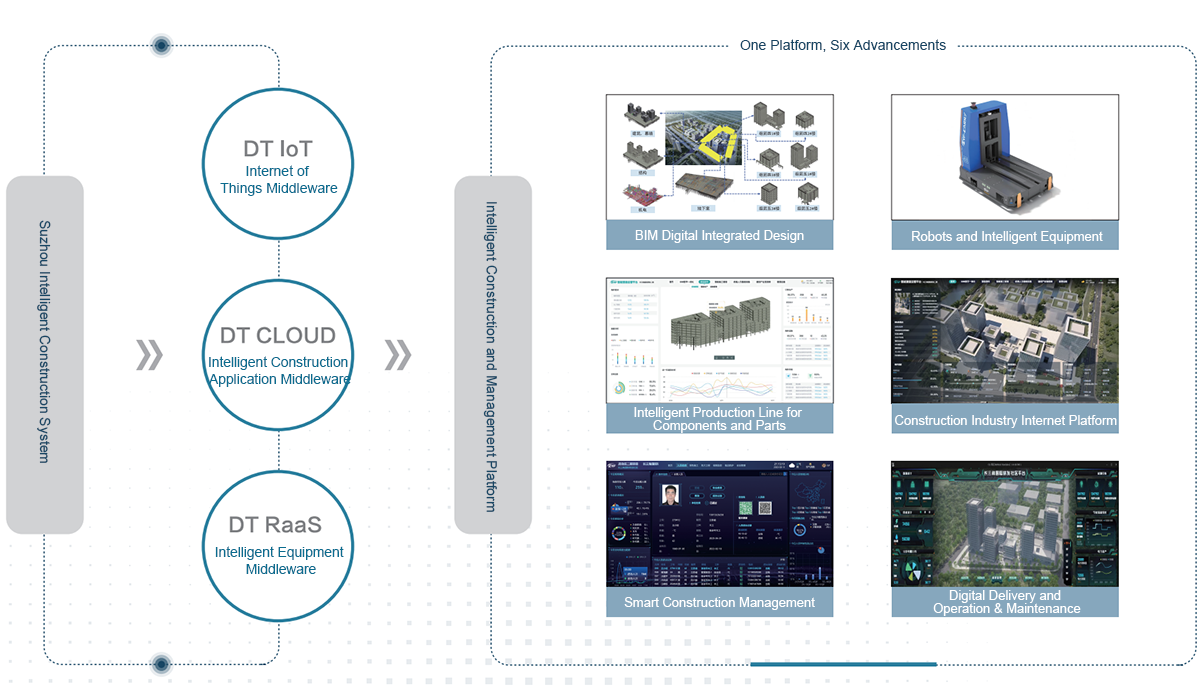

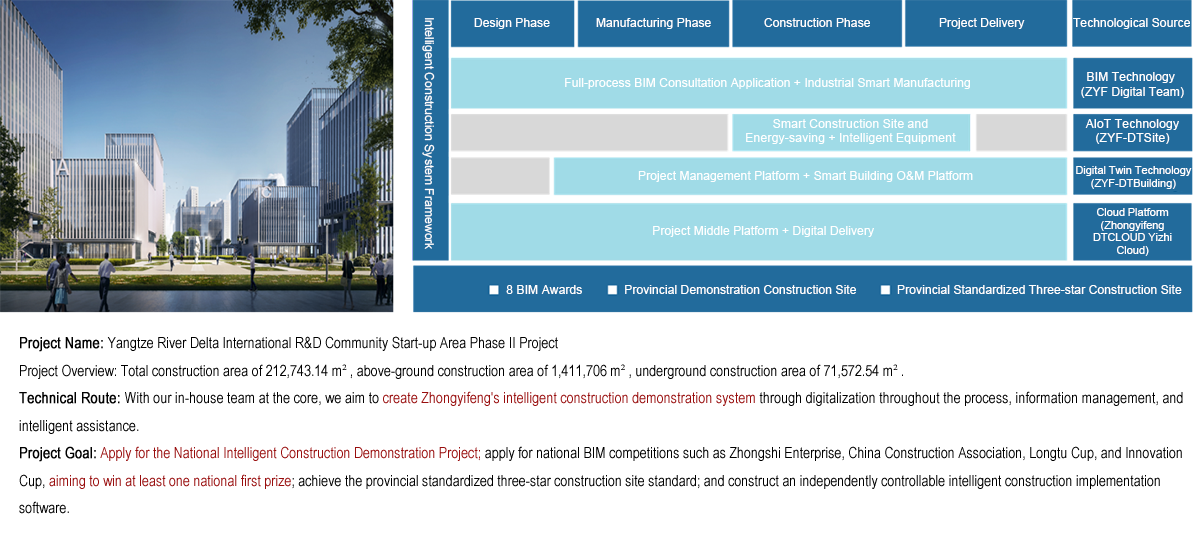

INTELLIGENT CONSTRUCTION

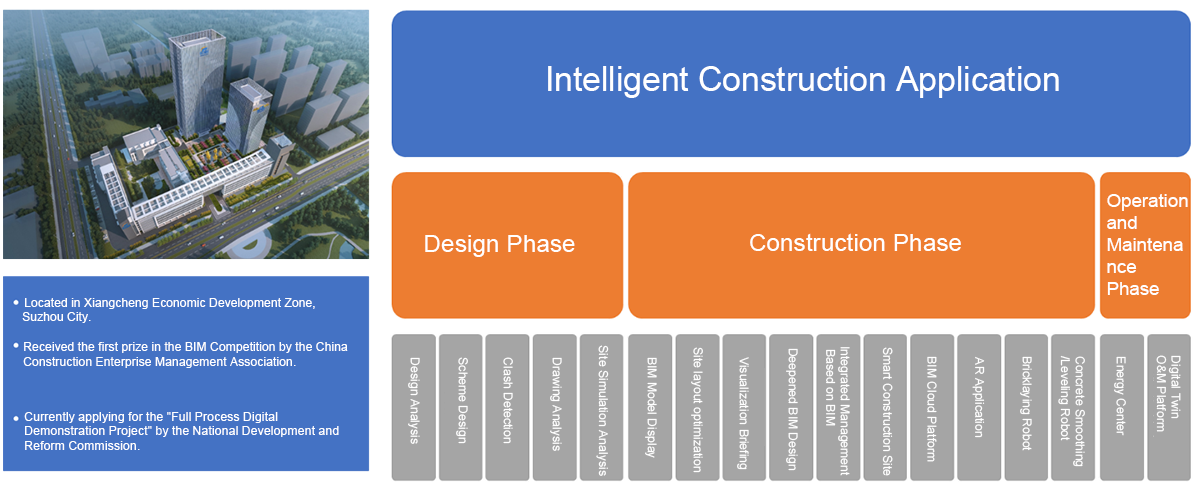

The Zhongyifeng Future Building Research and Development Center is an office building project independently invested in, designed, and constructed by the Zhongyifeng Group. This project, with the primary application focuses of "BIM + Smart Construction Site + Construction Robots + Energy Center", aims to create a showcase for intelligent construction.

The second phase of the Science and Innovation Park has a total construction area of about 170,000 square meters. Its structural form presents significant height differences with a non-planar tri-connected body. There are large-span steel structural corridors between the towers, and a significant amount of high-altitude cantilevered construction work is involved. To address the key and challenging aspects of the project's construction, a series of intelligent construction technologies are comprehensively adopted throughout the entire construction process. This includes digital specialized design deepening, component production, the application of intelligent equipment, and a project management platform based on the industrial internet.

Modernization of the construction industry

Zhongyifeng Construction Group Co., Ltd. 苏ICP备000000号-1